How can AAC give your business a competitive edge in the marketplace?

Contact us for your next project at 570-842-5842

Email: [email protected]

Our Services

| Concept Development | Robotics |

| Project Management | Electrical Construction |

Engineering and Design | Mechanical Fabrication |

| Automation and Controls | 24/7 Support |

Are You Protected from Arc Flash Hazards?

AAC provides highly qualified and efficient Arc Flash Risk Assessments to ensure employees are safe from fire and injury. Included in this service is an electrical system single-line diagram, an Arc Flash analysis including discrepancies and recommendations for improving safety and reducing hazards, and installation of corresponding Arc Flash labels.

Is Legacy Equipment Keeping You Down?

Is your machinery prepared for the new decade? Legacy equipment doesn’t have to slow down production speeds or efficiency. AAC specializes in retrofitting legacy machinery from global companies in a multitude of industries.

By retrofitting, you avoid the high costs associated with purchasing new equipment. Once AAC completes the concept design and engineering on the initial machine, it can then be applied to any remaining machines for additional cost savings.

Choosing a system upgrade over purchasing new results in exponential savings, faster installation, and superior service by AAC.

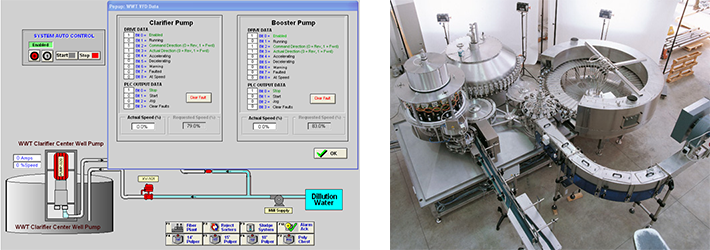

AAC is Juicing Up the Industry

Advanced Automated Controls is thrilled to showcase one of our most recent projects! Our highly skilled engineering team was involved in the concept design, engineering, fabrication, installation and commissioning of a complete juice manufacturing line for a highly reputable juice manufacturing company. The system consisted of all processing and material handling equipment and systems along with interaction to the customer’s Warehouse Management System (WMS), Automated Guided Vehicle System (AGV), and their Enterprise Resource Planning System (ERP). From raw materials to finished product, AAC provided the customer with the most efficient, reliable, and high-tech solutions in the industry to give them a competitive edge within their vertical markets.

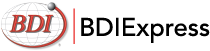

Suiting Up for Battle with Control System Upgrades

AAC is proud to have recently completed multiple control system upgrades for a leading global company in the defense industry regarding tracked and wheeled military vehicles. The major components of the original control system for this customer were antiquated and obsolete. The existing control system utilized information critical to the functionality of the machine in an antiquated custom analog servo controller interfaced to a servo valve. The system also included an obsolete and proprietary PC based operator interface that interfaced to the system via custom programming and configuration tools.

AAC upgraded the system to include the latest technology developed by Allen Bradley including an Allen Bradley CompactLogix PLC and a PanelView Plus HMI. The control system was simplified by developing the servo valve control into the PLC program, thereby eliminating the need for a servo drive and custom programming and communication configurations. The new control system maintained existing machine functionality along with added safety, operational, and functionality features making the system more flexible and robust.

Learn More about the partnership with Rockwell Automation

How can AAC give your business a competitive edge in the marketplace?

Contact us for your next project!